Our Products

Automated Treatment and Transport

Automated treatment and transport systems are the key to achieve high reliability, precision and cost efficiency in your alloy production.

Get your support from the Zorc Metallurgy Team in planning, implementation and optimisation. Let your melt shop be more effective: give the pouring area a higher flexibility and create the final alloy in the ladle. Reduce environmental issues: get rid of reaction gases through integrated exhaust systems.

All treatment hardware modules are included:

Get your support from the Zorc Metallurgy Team in planning, implementation and optimisation. Let your melt shop be more effective: give the pouring area a higher flexibility and create the final alloy in the ladle. Reduce environmental issues: get rid of reaction gases through integrated exhaust systems.

All treatment hardware modules are included:

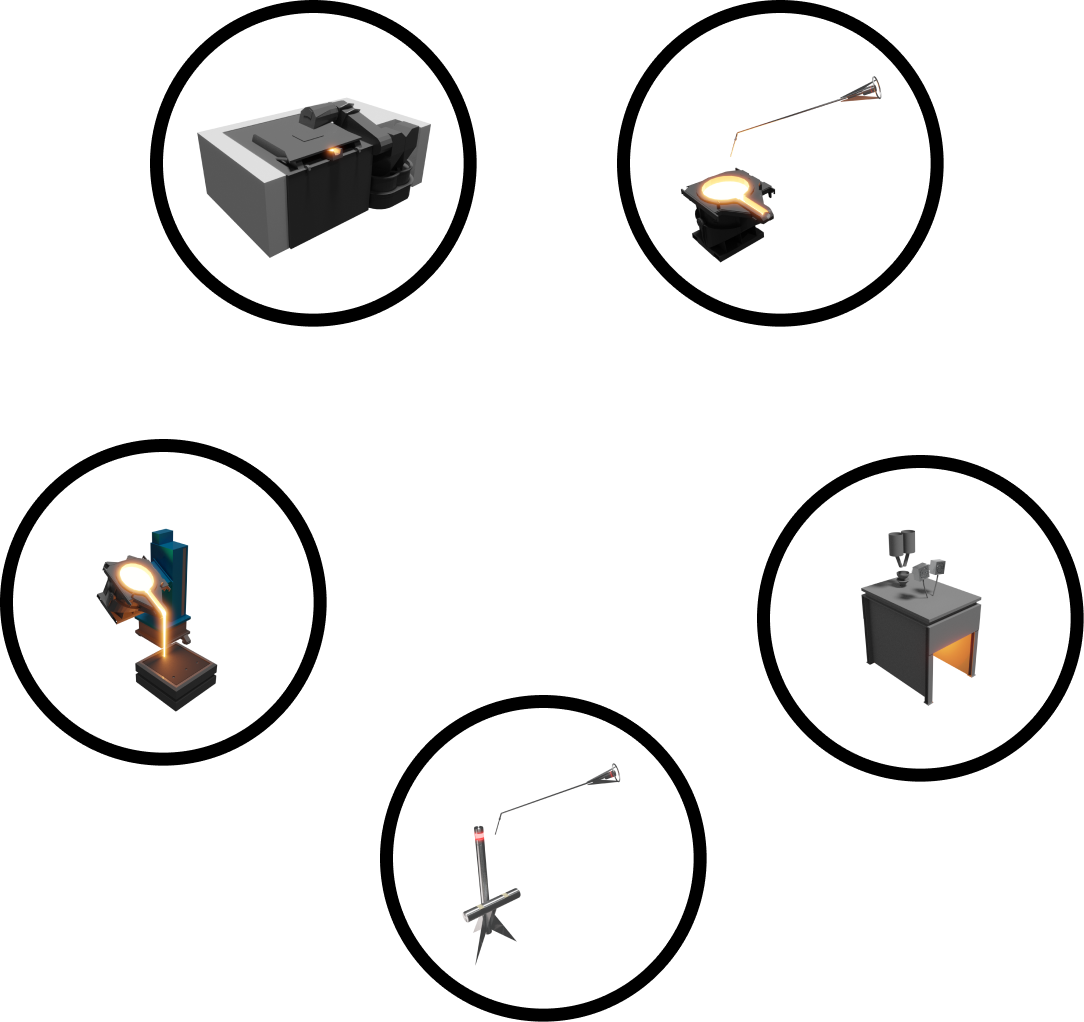

- Treatment system with magnesium / cerium wires

- Inoculation systems

- Bulk addition systems – add copper, ferrosilicon, Cerium or Carbon

- Addition of modification and grain refinement materials for AlSi-Alloys

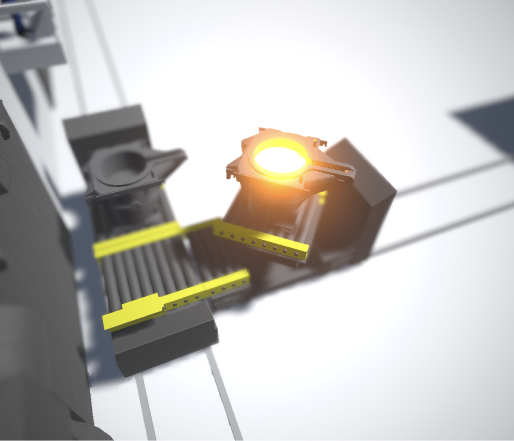

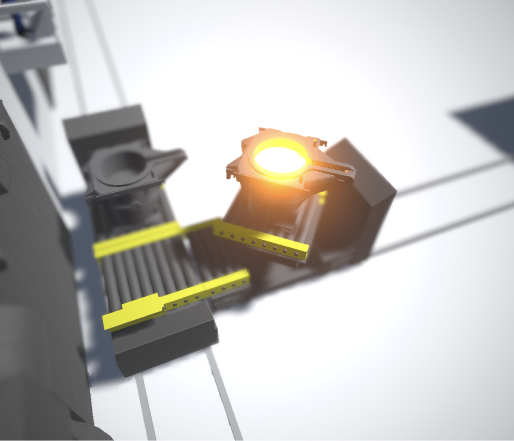

Transport Systems - Fast, efficient and safe

Increase safety and reduce costs by automatisation.

Replace forklift or crane transportation with ladle cars and roller conveyors. Start your automatisation at the furnace and connect it to treatment, deslagging and pouring.

All measurement systems and quality gates are integrated:

The software system is included in the package with:

The Software communicates easily with your ERP system.

Replace forklift or crane transportation with ladle cars and roller conveyors. Start your automatisation at the furnace and connect it to treatment, deslagging and pouring.

All measurement systems and quality gates are integrated:

- Phase transition analysis (PTA, evolved from a thermal analysis)

- Temperature measurement

The software system is included in the package with:

- SG/CGI pilot – automated calculations and workflow execution assistant that guides your workforce through the process.

- TransportManager – software to manage the logistics.

- SG/CGI manager to schedule the production.

The Software communicates easily with your ERP system.

Smart Foundry

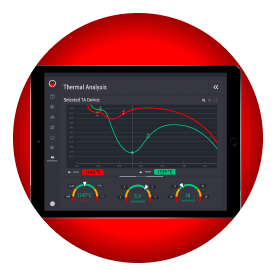

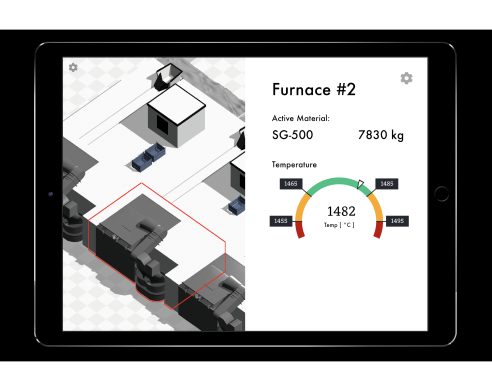

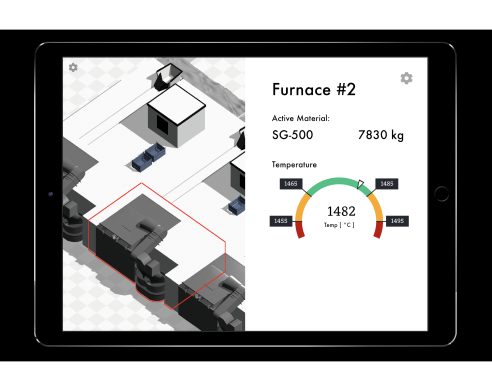

FoundryCloud

A highly flexible, easy to adapt, full scale manufacturing execution system (MES).

Using data science to get a better understanding of your processes, drawing the right conclusions for dynamic process optimisation.

Add cost effective tablet and hand held devices to your PC based technology, distributing information to all places in the production, from the worksite to the meeting rooms.

Install control processes and quality gates to achieve the best possible quality standards and documentation of your production.

The MaterialTracer will give you a higher insight into your material flow.

Using data science to get a better understanding of your processes, drawing the right conclusions for dynamic process optimisation.

Add cost effective tablet and hand held devices to your PC based technology, distributing information to all places in the production, from the worksite to the meeting rooms.

Install control processes and quality gates to achieve the best possible quality standards and documentation of your production.

The MaterialTracer will give you a higher insight into your material flow.

DigitalTwin

Experience the power of visualisation for process understanding and optimisation. Get an overview of the KPIs of your production and state of your machines at a glance.

ZIOM - zOrc Intranet of Machines

Professional IOT devices for your industry.

Save your investment by upgrading your existing machines to Industry 4.0: connect via industrial ethernet, IO-Link, digital IOs or retrieve data direct from sensors.

Use an on-site server and your internal firewalls for an intranet installation or go for the secure but cost efficient cloud solution.

Save your investment by upgrading your existing machines to Industry 4.0: connect via industrial ethernet, IO-Link, digital IOs or retrieve data direct from sensors.

Use an on-site server and your internal firewalls for an intranet installation or go for the secure but cost efficient cloud solution.

Metallurgical Process Control

GJV/GJS Pilot

The most integrated CGI and SG production system on the market: Utilise the power of machine learning to profit from continuous optimisation.

Let the SG/CGI Pilot guide your workforce through the day to day alloy production process and take care of the necessary calculations and corrections to keep the output as stable as possible. Keeps you away from typical metallurcical problems like porosity or variation in mechanical properties.

Let the SG/CGI Pilot guide your workforce through the day to day alloy production process and take care of the necessary calculations and corrections to keep the output as stable as possible. Keeps you away from typical metallurcical problems like porosity or variation in mechanical properties.

PhaseTransitionAnalysis - PTA

The Evolution of Thermal Analysis:

Adds heat flow measurement for individual solidification zones to achieve better results in a wide range of CE values, from hyper- to hypoeutectic alloys. Giving the metallurgist an insight into its decisions.

Adds heat flow measurement for individual solidification zones to achieve better results in a wide range of CE values, from hyper- to hypoeutectic alloys. Giving the metallurgist an insight into its decisions.

IndexCoin and MetaCoin

Our new thermal analysis sensor series

- Delivering FAST and accurate results

- Does not harm the health of your workforce

- Is cost efficient and environmentally friendly